SHIP PURIFIER INLINE WATER SENSOR

EESIFLO Water monitor on Lube Oil Purifiers for Ships

It is common knowledge in the marine industry that machinery needs to be lubricated. Lubrication oil reduces heat by lowering frictional forces that act on machine parts which in turn increases the lifespan and effectiveness of moving parts.

Good lubrication practices also protect machinery from oxidation, acid effects, corrosion , pitting, scarring and any unwanted irregularity on a metal surface that not only increases friction, wear and tear but also a decrease in performance. The right lube oils for purifier and separator systems will reduce the impact of rubbing to more of a “sliding” effect.

Main Engine Lube Oil Systems

Just like in any other industrial setting where “power machines” are operating, the main engine of a ship has it’s own lube oil system. Lube oil quality has to be maintained to a level that does not cause main bearing damage or premature failure. Very often (because bearing damage is not immediate) a lackadaisical approach ensues. We interviewed several ship captains some years ago to discuss the effectiveness of their lube oil spot sampling and it was no surprise to confirm that one of the main issues with the ineffectiveness of lube oil spot sampling had to do with the responsibility that was placed on individuals to diligently take the samples at regular intervals. Of course, the captains had records of the sample values but were unsure whether the sample data was correct, not due to the instruments used to measure the water content and other contaminants – but because the question remained “Were all those samples actually taken?” One of the ship captains opted for the implantation of an inline water in oil sensor so that at least a comparison could be made and personnel knew that a device was in place to compare with their spots samples. In other words, the inline sensors were purchased to ensure that those responsible for taking lube oil samples were more likely to carry out sampling conscientiously, knowing that an instrument was in place that reports the water content in real-time. Attention must be paid to the regular upkeep and maintenance of lube oil pumps, filters, guides, pistons, bearings, joints, cylinders, nozzles, quills and liners which can all be affected by water, especially “free water”. The reason why more attention should be focused on inline/online water in oil sensors is because when failures occur, they are very often due to water contamination. It might be the case that nobody is exactly sure where the trouble begins. The online water in oil sensor is a useful tool from the very start of any sequential event investigation, since too much water in lubrication systems is definitely going to affect all of the above mentioned components in a system.

Inline Sensors an Additional Tool for Free Water Detection in Oil Purifiers and Centrifuges

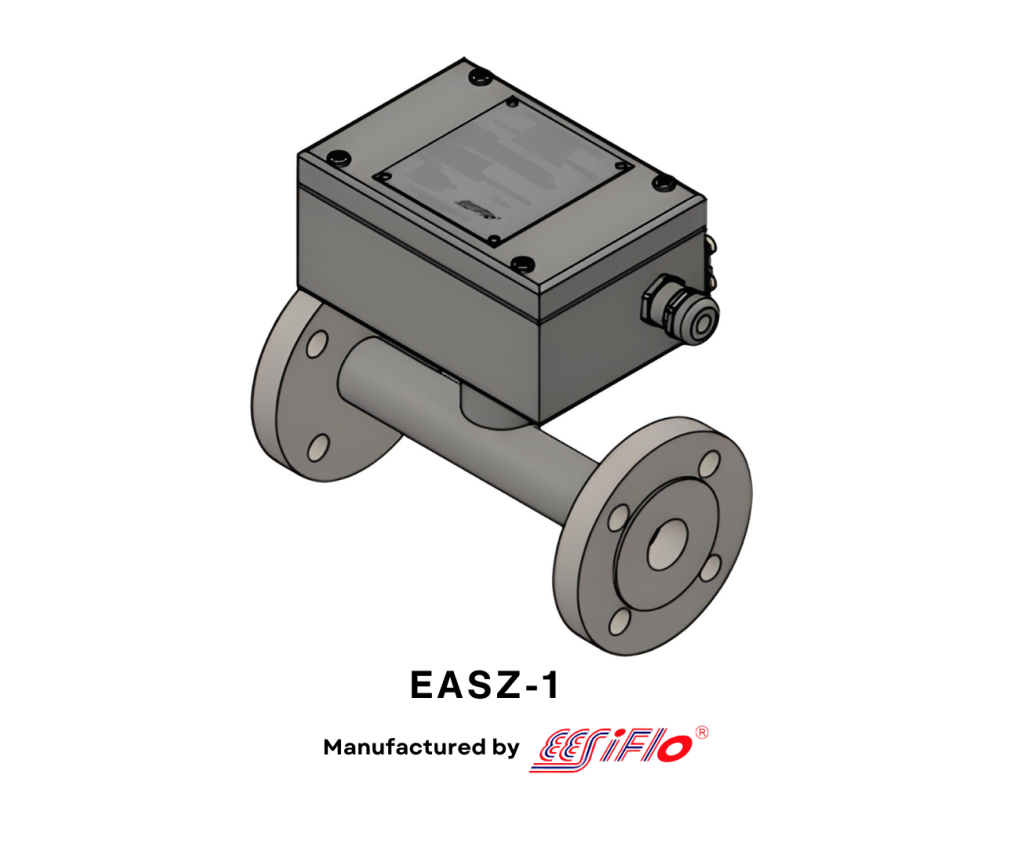

Engineers and technicians are appointed to keep watch (watchkeeping task) of the quality of a lube oil including lube-oil temp, pressure values and lube oil properties after the oil has been used. The EASZ-2 does not use a “water activity” approach. The technology is a direct measurement of water content irrespective of the saturation level of the oil. Oil is not supplied or sold by oil manufacturers according to a saturation level but according to the amount of water that is present. Normally this should be a very small amount to keep within the product specification. Water in oil sensors using the water activity approach are limited because they do not detect the presence of free water. Their implementation is simply cosmetic. They work on the assumption that the presence of “free water” in a lube system is less common than expected. The EESIFLO inline water sensor can pick up a gradual and most importantly a “sudden” increase in moisture content because the working principle behind it’s operation does not depend on saturation levels of the oil but instead a direct measurement of the dielectric constant value of the liquid.

Ship Purifiers

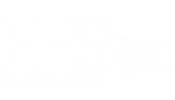

Everyone needs Lube oil purifiers and on initial purchase of a ship oil purifier, it might not of been deemed necessary to install an optional inline water in oil sensor on the outlet because of economical reasons or because it was not part of the initial engineering plan. Despite this, EESIFLO’s online water in oil sensors can be easily retrofitted on a later date to the outlet of any brand of Purifier whether it is manufactured by Alfa Laval, Mitsubishi, GEA or others. We have supplied and have installations on almost every type of purifier whether it uses the gravity, centrifugal method, filtration technology (coalescence) and even special vacuum purifiers. Most of the applications that we have installed the EASZ-1 and EASZ-2 sensors to have been on high speed ship purifiers for oil, since a high speed purifier is working at “high speed’ and hence a fast response (once per second) water in oil sensor can pick up any changes that have occurred the the oil’s water content. In some cases, the user prefers a simple PLC to ignore the readings during the purifier desludge cycle if is found that a larger amount of water has made it’s way into the outlet piping during desludge operations.

Ship Oil Centrifuge

A centrifuge in some ways could be considered to be a gravity separator that speeds up seperation by combinding centrifugal force. Oil is cleaned and sent back to the system while the water is literally spat out through the discharge areas of the centrifuge while particles are collected in the well known bucket/bowl.

Since a higher oil temperature will lower viscosity and make the job of the centrifuge much easier, an inline sensor must be able to work at higher temperatures. EESIFLO’s sensing elements are made in stainless steel with PEEK inserts for high temperatures.

We have experience onboard all types of ships and have installed EESIFLO water in oil sensors in Singapore, Busan Korea, Japan, Rotterdam and have worked with the US Coastguard to supply moisture in oil sensors for various engine room applications. More information on moisture in oil sensors for marine applications at EESIFLO’s website.