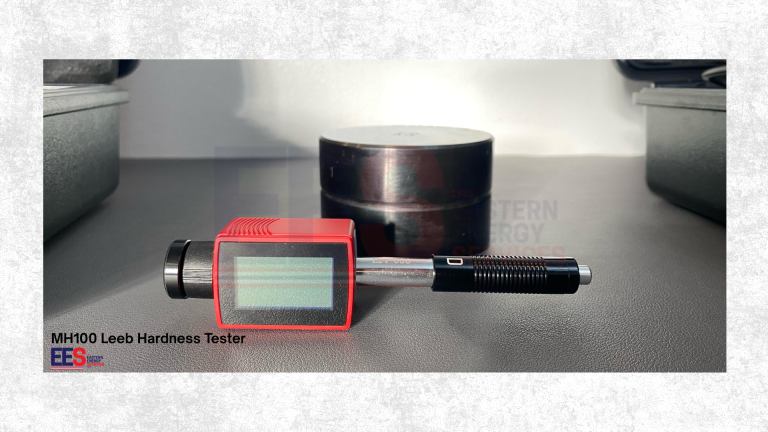

MH100 Leeb Hardness Tester

MH100 series pocket hardness meters, also known as pen-type hardness tester, based on Leeb hardness measuring principle, quick and easy on-site test the hardness of series metal materials, support free conversion between Richter, Brinell, Rockwell hardness scale and others, integrated compact design, small size, portable, highly integrated, stable and reliable performance, supporting data transfer and print the stored function. Widely used in failure analysis of metal processing and manufacturing, special equipment, permanent assembly, inspection and other fields. Particularly suitable for large parts and non-removable part of the site hardness testing. It is professional precision instrument to improve the pass rate of production and cost savings .

Leeb Hardness Testing Principle

The Leeb Hardness Tester is highly regarded for its portable, efficient, and non-destructive approach to measuring the hardness of metallic materials.

The basic principle is to use an impact body of certain weight impacts against the testing surface under certain test force, then measure the impacting velocity and the rebounding velocity of the impact body respectively when the spherically test tip is located 1mm above the testing surface.

The calculation formula is as follows:

HL=1000 x VB/VA

Where,

HL – Leeb hardness value

VB – Rebounding velocity of the impact body

VA – Impacting velocity of the impact body

A small, weighted object is dropped onto a surface with a set amount of force. The device measures how fast it hits and how fast it bounces back. The harder the surface, the faster it rebounds. This helps determine the material’s hardness.

MH100 Pen-type Hardness Tester

- The impact device is seamlessly integrated with the main body, ensuring compact functionality.

- Utilizing the principles of Leeb hardness testing, it accurately measures the hardness of all metallic materials.

- A large LCD screen displays all functions and parameters clearly.

- The device allows testing from any angle, including upside down.

- It features USB connectivity for easy data transfer to a PC.

- Additionally, its large memory can store up to 100 sets of information (impact times 32 ~ 1), including individual measurements, average values, impact direction, number of impacts, material type, and hardness scale.

- Measuring range: (170~960) HLD

- Impact direction: Vertically downward, oblique, horizontal, oblique, vertical upward, automatically identify

- Error: Impact device D:±6HLD

- Repeatability: Impact device D:±6HLD

- Material: Steel and cast steel, cold work tool steel, stainless steel, grey cast iron, nodular cast iron, cast alum

- Hardness Scale: HL、HB、HRB、HRC、HRA、HV、HS

- Min depth for harden layer: D≥0.8mm;C≥0.2mm

- Display: High-contrast Segment LCD

- Storage: Up to 100 groups (Relative to average times 32~1)

- Calibration: Single point calibration

- Data printing: Connect PC to print

- Working voltage: 3.7V (Built-in lithium polymer battery)

- Power supply: 5V/500mA;recharge for 2.5~3.5 h

- Standby period: About 200h (without backlight)

- Communication interface: USB1.1

- Working temperature: – 10℃~+50℃

- Storage temperature: -30℃~+60℃

- Relative humidity: ≤90%

- Shell material: ABS engineering plastic

- Dimensions: 148mm×33mm×28 mm

- Total weight: 4.0KG

- PC software: Yes

- The surrounding environment should avoid of vibrations, strong magnetic field, corrosive medium and heavy dust.

- Die cavity of molds.

- Bearings and other parts

- Failure analysis of pressure vessel, steam generator and other equipment

- Heavy work piece

- The installed machinery and permanently assembled parts.

- Testing surface of a small hollow space

- Requirements of formal original record for test results

- Material identification in the warehouse of metallic materials

- Rapid testing in large range and multi-measuring areas for large-scale work piece