Dust Monitoring Solutions

Sintrol dust monitors reduce discovery time for filter malfunctions, thereby, reducing maintenance costs, preventing equipment contamination and product loss, and ultimately increasing plant availability. Sintrol monitors are of the highest quality and most advanced technology.

Sintrol EXO Dust Monitor

Continuous Dust levels as low as 0,1 mg/m³

EXO dust monitor consists of a heated sampling probe, optical XO sensor module, and an integrated panel PC, which are housed in a weather-proof powder-coated steel enclosure that is mounted on a frame. In a complete installation, the probe is inserted inside a stack perpendicular to the airflow using a flange. An external sample air blower supplies air to an ejector chamber at the end of the sampling line, creating a vacuum effect that draws flue gas through the internal piping of the device and ejects it back into the stack.

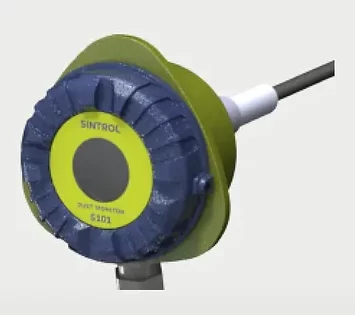

Sintrol S101/S103 Filter Monitor

The S101 variant includes two relays to indicate dust alarms, while the S103 version comes with an active and isolated 4...20 mA output.

The S100 series is a basic cost-effective dust monitor to give an indication of changes in dust levels from the gas flow. This robust and sensitive monitor can be used in duct sizes with a diameter of less than 1 meter. The S100 is a real-time continuous dust monitor and will monitor for leaking or broken filters.