MH310 LEEB Hardness Tester

MH310 portable Leeb hardness tester, based on Leeb hardness measuring principle, quick and easy on-site test the hardness of series metal materials, support free conversion between Leeb, Brinell, Rockwell hardness scale and others, it uses high-contrast segment LCD to display clear, stable performance. integrated high-speed thermal printer, which can print on-site measurements. It is widely used in annealing, tempering, quenching, quality control for the work piece; hardness testing for machine tool and automobile chassis; on-site hardness testing of in-service non-removable parts; quality testing for hardware, forging, machine tools and special steels; quality control for batch production process and so on. Good quality and effective cost, which is a wise choice for regular need of hardness testing.

Working Principle

The energy quotient is quoted in the hardness unit HL and is calculated from comparing the impact and rebound velocities of the impact body. It rebounds faster from harder samples than from softer ones, resulting in a greater energy quotient which is defined as 1000×Vr/ Vi.

HL=1000×Vr/ Vi

Where:

HL— Leeb hardness value

Vr — Rebound velocity of the impact body

Vi — Impact velocity of the impact body

- Capable of measuring a wide range of metallic materials.

- With EL background light; showing all functions and parameters.

- Automatically identify the type of impact devices.

- Test at any angle, even upside down.

- Can store 100 groups information including single measured value, mean value, impact direction, impact times, material and hardness scale.

- Software to connect to PC via USB port.

- Thermal printing integrated convenient for in field printing.

- Measuring Range: (170~960) HLD

- Impact direction: Vertically downward, oblique, horizontal, oblique, vertical upward, automatically identify

- Error: D, ±6 HLD

- Repeatability: D, 6 HLD

- Material: Steel and cast steel, cold work tool steel, stainless steel, grey cast iron, nodular cast iron, cast aluminum.

- Hardness Scale: HL、HB、HRB、HRC、HRA、HV、HS.

- Impact Energy: D—-11mJ

- Impact Weight: D—-5.5g/7.2g

- Impact Ball Hardness: D—1600HV

- Impact Ball Diameter: D—-3mm

- Impact Ball Material: D—-Tungsten Carbide

- Sample Surface Roughness: D—-1.6μm;C—-0.4μm

- Min Depth of Harness Layer: D≥0.8mm;C≥0.2mm

- Display: High-contrast segment LCD

- Storage: 100 measurement series (Relative to average times 32~1)

- Calibration: Single point calibration

- Data Printing: Print the test report

- Power Voltage: 6V (Ni-MH battery pack)

- Power Supply: 9V/500mA;recharge for 2.5~3.5h

- Power Consumption: Lower power design

- Standby Period: about 150 hours (with default brightness)

- Communication Port: USB1.1

- Working Language: English

- Working temperature:- 10℃~+50℃.

- Storage temperature:-30℃~+60℃

- Relative humidity: ≤90%.

- The surrounding environment should avoid of vibration, strong magnetic field, corrosive medium and heavy dust.

- Steel and Cast steel

- Stainless steel

- Nodular cast iron

- Gray cast iron

- Cast Aluminium

- Brass, bronze and copper

- Automotive and Aerospace – Ensuring that components such as gears, bearings and structural parts adhere to the necessary hardness standards.

- Metals and Alloys – Assessing the strength, wear resistance and durability is crucial in the fields of manufacturing and engineering.

- Research and Development – Analyzing material properties to support innovation and the creation of new products.

- Manufacturing and Quality Control – Ensuring material hardness for consistent production quality.

- Construction and Mining – Conducting evaluations of metals to determine their structural strength, durability and suitability for construction and engineering applications.

The Leeb Hardness Tester is a compact, portable device for quick hardness testing of metals. It uses the Leeb principle and support conversions between different hardness scales…Read more

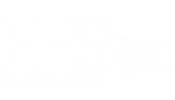

It can automatically detect both magnetic and non-magnetic substrates, facilitating a smooth conversion process. Furthermore, it enables quick testing of coating and layer thickness…Read more

Surface roughness measuring instruments are employed to assess the subtle irregularities on a material’s surface. These variations are crucial as they can significantly influence the performance, quality, and functionality of products in various industries…Read more

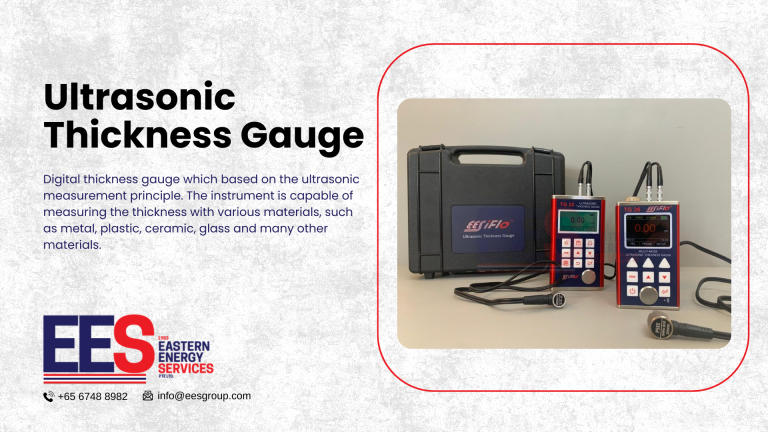

The digital ultrasonic thickness gauge determines the thickness of a part or structure by accurately measuring the time required for a short ultrasonic pulse generated by a transducer to travel through the thickness of the workpiece…Read more